What we know today as AMSCO® has a long, winding history that dates back all the way to 1795.

The AMSCO® name, which stands for American Manganese Steel Company, came along in October of 1915. The first time it appeared on a casting was in 1916.

So what preceded the AMSCO® name? Here’s a brief look at the history of the company.

1795: The Ramapo Works

The Ramapo Works was established in Ramapo, New York by Josiah Pierson. The rolling milling, slitting mill and nail factory was on 119 acres of land and employed up to 300 people. The mill preceded other foundries and forges in the immediate area. It closed in 1853 when the dam across the Ramapo River broke.

1824: John and Andrew Suffern

By this date, John Suffern and his son Andrew had a sizable iron forging business in New Antrim, New York. They made nails, barrel hoops, crowbars, wagon tires and axles, axe heads, bar iron and more. After John Suffern’s death, the town of New Antrim was renamed to Suffern, New York.

Customers of Suffern’s business:

–Ringwood Ironworks in Ringwood, New Jersey. It operated a blast furnace and forges starting in 1742. They helped produced the “Great Chain,” which helped prevent British ships from traveling up the Hudson River during the Revolutionary War. The last blast at the furnace was in 1879. However, today you can still visit the Ringwood grounds at Ringwood Manor state park.

–Sterling Ironworks in Sterling Lake, New York. It operated a blast furnace and forges that opened in 1736. It is said Sterling was commissioned to do the “Great Chain” across the Hudson, and they used several other forgers and foundries, like Ringwood, to help with the massive project. The last blast furnace there was shut down in 1891. A reconstructed blast furnace and mine structures still exist at Sterling Lake.

-Southfield Ironworks in Tuxedo, New York. A charcoal-fired blast furnace that opened in 1806. Transferred to anthracite coal as fuel in 1887. Furnace still stands in northern part of Tuxedo, New York.

1850: Rochester, New York foundry

A foundry was established in Rochester, New York to make cast iron wheels for railroad cars. One of the owners was the brother of famed circus owner P.T. Barnum. The foundry later became one of four owned by National Car Wheel Company.

1852: Suffern establishes forge in Hillburn, New York

James Suffern, the grandson of John Suffern, established a charcoal-fueled forge in Hillburn, New York along the Ramapo River. The forge had two fires, two hammers, a puddling furnace to convert pig iron into wrought iron and a rolling mill. Railroad axles were a big part of the forge’s business.

It later became part of the Ramapo Iron Works.

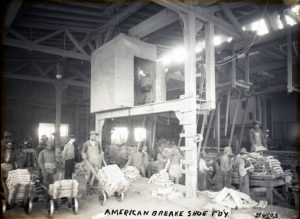

Bottom: Workers at the Ramapo Iron Works in 1904

(Courtesy: Suffern Free Library)

1866: Ramapo Wheel Foundry

The Ramapo Wheel Foundry was established in Ramapo, New York. William W. Snow was a director and officer at the foundry.

1881: Ramapo Iron Works was formed

The Ramapo Iron Works was formed, largely by the owners of the Ramapo Wheel Foundry. The iron works built an iron foundry and other metalworking facilities on 20 acres of land in Hillburn, New York. That land was purchased from James Suffern, John Suffern’s grandson.

The foundry’s major product was railroad switches.

1882: Manganese steel is produced for the first time

Robert Hadfield produced manganese steel for the first time in Sheffield, England, He was later knighted and he received the first patent for manganese steel a year later.

1901: Ramapo Foundry Company is formed

Using the assets of the foundry portion of the Ramapo Iron Works, the Ramapo Foundry Company was formed.

William W. Snow was President of the newly formed company. The company began constructing a new iron foundry that same year in Mahwah, New Jersey. It was completed in 1902 and made railroad brake shoes.

The Mahwah, NJ foundry closed in 1984.

1902: American Brake Shoe and Foundry Company is formed

Six foundry companies joined together to form the American Brake Shoe and Foundry Company.

The companies were:

-The Ramapo Foundry Company (Ramapo, NY)

-Sargent Company (Chicago, IL)

-Corning Brake Shoe Co. (Corning, NY)

-Ross-Mehan Foundry Co. (Chattanooga, TN)

-Lappin Brake Shoe Co. (Bloomfield, NJ)

-Streeter Brake Shoe Co. (Chicago, IL)

William D. Sargent was the American Brake Shoe and Foundry Company’s first president. He was succeeded by Otis Cutler in 1903.

1906: Hadfield’s patent on manganese steel expires

Robert Hadfield’s patent on the manganese steel he created expires in the United States. That’s when American Brake Shoe and Foundry Company began making manganese steel in Chicago Heights, Illinois.

1910: The Edgar Allen American Manganese Steel Company

The American Brake Shoe and Foundry Company formed a subsidiary, the Edgar Allen American Manganese Steel Company. That included the facility in Chicago Heights, IL.

The Edgar Allen American Manganese Steel Company also acquired a foundry in New Castle, Delaware, formerly known as the Tropenas Steel Company.

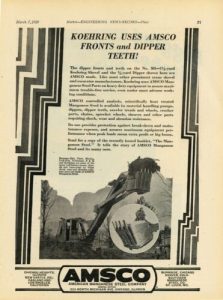

1911: The first all-manganese steel power shovel dipper

The Chicago Heights facility patented and produced the first all-manganese steel power shovel dipper. It was called the “Missabe Dipper.” They also developed the Vanderhoef dipper tooth.

Both of those products were put to work on the Minnesota iron range and the Panama Canal excavation.

1915: Edgar Allen changes its name to the American Manganese Steel Company

The Edgar Allen American Manganese Steel Company changed its name to the American Manganese Steel Company. This was the birth of AMSCO® The trademark was first used on castings in October of 1916.

We will explore the AMSCO® history from 1915 to the present in our next blog.

Sources and References

American Brake Shoe and Foundry Company Annual Reports, 1920 to 1945.

AMSCO Bulletins, 1928 to 1969.

Numerous historic documents on file at AMSCO Wear Products in Goshen, NY.

Oliver and Boyd, Manganese Steel, published for Hadfields Limited, Sheffield, England, 1956.